Home // Blog

In the realm of plumbing projects, understanding the intricacies of plastic pipe fittings is crucial for achieving both efficiency and reliability in installations. According to a 2022 report by the Plumbing Manufacturers International, the plastic pipe fittings market has experienced a steady growth rate of approximately 5.3% annually, driven by the increasing demand for lightweight and corrosion-resistant materials. This surge highlights the importance of knowledge in selecting the right fittings for various plumbing applications, underpinning the need for informed choices by professionals and DIY enthusiasts alike.

Industry expert and technical consultant Dr. Emily Carter emphasizes, “The selection of appropriate plastic pipe fittings not only impacts the longevity of plumbing systems but also plays a significant role in minimizing water wastage.” As the plumbing industry continues to evolve with innovative materials and techniques, staying updated on the top plastic pipe fittings is vital for anyone involved in plumbing projects. In this article, we delve into the top 10 plastic pipe fittings that every plumber should be familiar with, combining expert insights with practical applications to elevate your plumbing endeavors.

When embarking on plumbing projects, understanding the variety of plastic pipe fittings is crucial. These fittings are essential for connecting different sections of piping and ensuring a leak-free system. Among the essential types are elbows, which allow for directional changes in piping, and tees, which enable branching into multiple directions. Couplings, another critical fitting, are used to connect two pieces of pipe together, facilitating repairs or extensions without replacing entire sections.

In addition to elbows, tees, and couplings, other notable fittings include caps and plugs, which are used to seal the ends of pipes, preventing unwanted flow. Flanges provide a stable and secure connection between piping systems, making them ideal for more significant projects. Lastly, unions simplify disassembly of piping systems for maintenance or replacement, allowing for easy access without damaging the plumbing setup.

Familiarizing yourself with these fittings will ensure your plumbing projects are both efficient and durable.

Plastic pipe fittings have become increasingly popular in plumbing projects due to their numerous key features and benefits. One of the primary advantages of plastic fittings, particularly those made from PVC or CPVC, is their resistance to corrosion and chemical damage. According to the Plastics Pipe Institute, plastic pipes are not only lightweight, making them easier to handle, but they also do not rust or corrode like metal pipes, leading to a longer lifespan and reduced maintenance costs. This resilience can save homeowners significant amounts in repair costs over time, particularly in environments prone to moisture and chemicals.

Another notable benefit is the enhanced energy efficiency provided by plastic fittings. The lower thermal conductivity of plastics means that water temperatures are maintained more effectively, reducing energy consumption associated with heating and cooling systems. A report by Global Market Insights indicates that the rising adoption of energy-efficient plumbing solutions is driving the growth of the plastic pipe fitting market. Additionally, the installation process for plastic fittings is often simpler and less labor-intensive than traditional materials, contributing further to overall project efficiency and cost-effectiveness. With these advantages, plastic pipe fittings are a compelling choice for modern plumbing projects, blending durability with practical benefits that appeal to both contractors and homeowners alike.

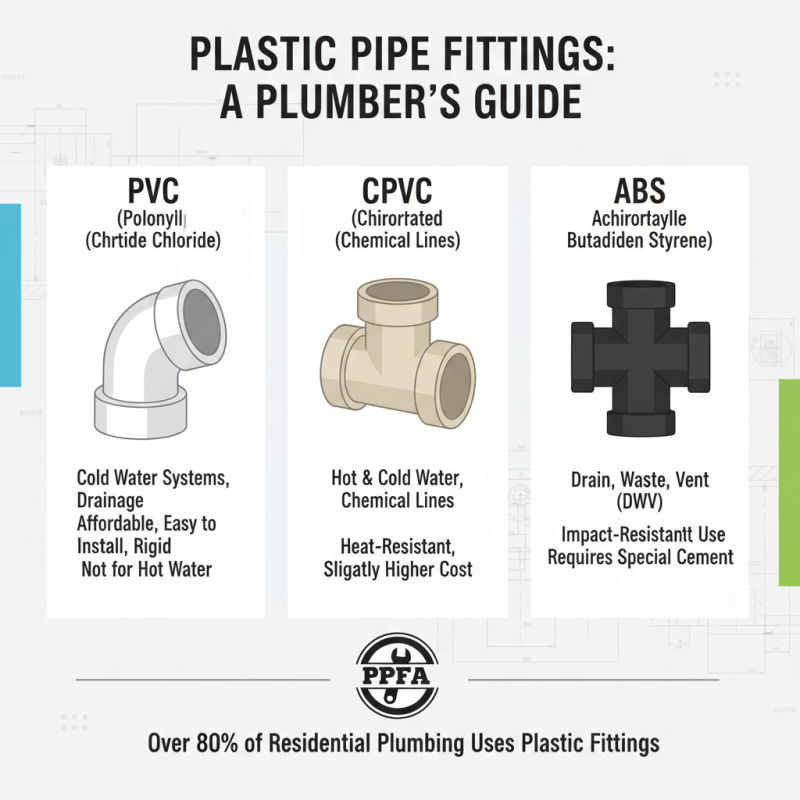

When embarking on plumbing projects, selecting the right plastic pipe fittings is crucial for achieving optimal performance and durability in your systems. Various materials such as PVC, CPVC, and ABS are popular in construction for their lightweight, corrosion-resistant properties. According to a report by the Plastic Pipe and Fittings Association (PPFA), over 80% of residential plumbing systems utilize plastic fittings due to their affordability and ease of installation. Understanding the specific needs of your project and the environment will help to determine the most appropriate fitting type.

To begin the selection process, consider factors such as the temperature and pressure requirements of your plumbing system. For high-temperature applications, CPVC may be more suitable than PVC, which has a lower tolerance. Additionally, ensure compatibility with the types of pipes you are using. The American Society for Testing and Materials (ASTM) provides standardized specifications for various fittings, helping to ensure that your choices meet safety and performance standards. Moreover, it's essential to pay attention to the fitting sizes and threading types, as this will affect the overall connection and flow efficiency of your plumbing system. Making informed choices based on these guidelines and industry data will lead to successful and durable plumbing solutions.

Plastic pipe fittings are essential components in plumbing systems, widely used for various applications due to their durability, lightweight nature, and resistance to corrosion. One of the most common applications of plastic fittings is in residential plumbing where they connect pipes for water supply and drainage systems. These fittings can easily accommodate changes in direction, allowing for efficient routing of plumbing lines around obstacles. Whether it’s a simple kitchen remodel or a more extensive plumbing overhaul, plastic fittings provide a reliable solution for both potable water systems and waste management.

In commercial settings, the versatility of plastic pipe fittings proves invaluable. They are often employed in industrial applications, such as chemical processing and wastewater treatment, where their resistance to chemical wear makes them ideal. Additionally, these fittings facilitate the installation of sprinkler systems, ensuring effective irrigation and fire safety measures. Their lightweight design reduces installation time and labor costs while still maintaining performance under various pressure conditions. As plumbing technology continues to advance, the role of plastic pipe fittings remains central to the efficiency and reliability of plumbing systems across diverse applications.

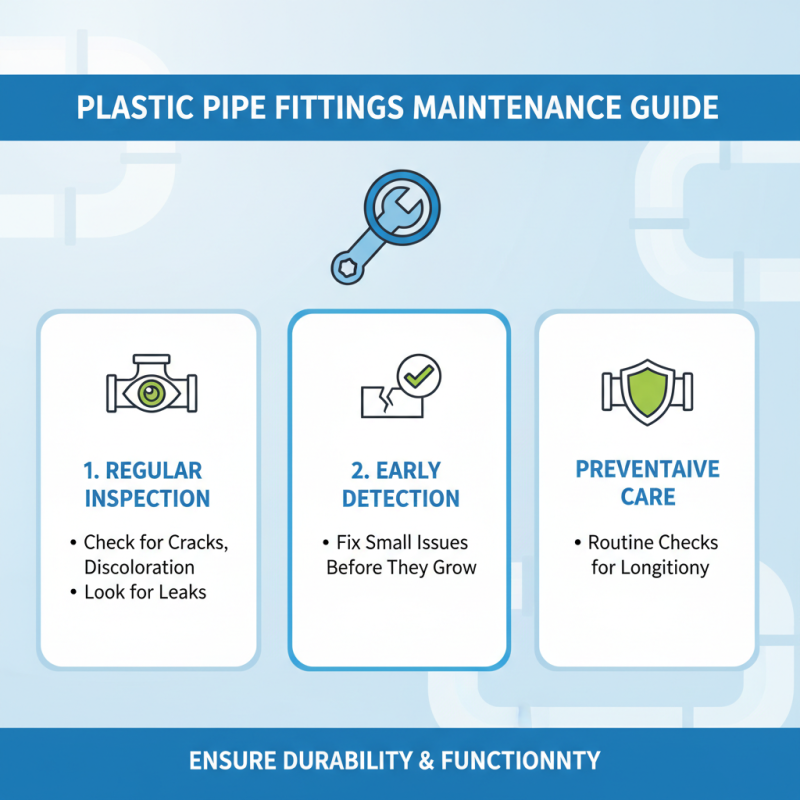

Maintaining plastic pipe fittings is essential for ensuring their longevity and functionality in any plumbing project. Regular inspection is the first step to effective maintenance. Check for signs of wear, such as cracks, discoloration, or leaks. Small issues, if caught early, can often be resolved before they lead to significant problems. Make a habit of examining the fittings during routine plumbing checks, especially if they are exposed to elements that could cause degradation over time.

Proper installation also plays a crucial role in the lifespan of plastic pipe fittings. Ensure that fittings are correctly aligned and tightly secured to prevent stress and potential damage. Utilizing the right tools and techniques during installation minimizes the risk of over-tightening, which can compromise the integrity of the fittings. Additionally, avoid exposing plastic fittings to extreme temperatures or harsh chemicals, as these can weaken the material. By adhering to these maintenance tips, you can significantly enhance the durability of your plastic pipe fittings, ensuring they serve their purpose effectively for years to come.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.