Home // Blog

Pipe fittings are essential components in various piping systems. They connect different sections of pipes, enabling the flow of fluids and gases. Understanding pipe fittings and their types is crucial for any plumbing or construction project.

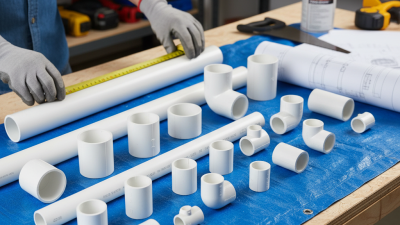

There are several types of pipe fittings, each designed for specific uses. Elbows allow for directional changes, while tees enable branch connections. Different materials, such as PVC and metal, influence their performance and suitability. Yet, choosing the right fitting isn't always straightforward. Misjudgments can lead to leaks and failures.

To ensure a successful installation, it’s important to consider factors like pressure ratings and compatibility. The details matter. Pipe fittings come in various sizes. The wrong size can affect flow rates dramatically. Therefore, careful planning is needed. Pipe fittings may seem simple, yet they play a vital role in system efficiency and longevity. Reflecting on this can lead to better decision-making.

Pipe fittings are essential components used in piping systems. They join, change direction, or branch pipes, ensuring fluid flows smoothly. Common types include elbows, tees, reducers, and couplings. Each serves a specific function. Elbows change the pipe direction, usually at a 45 or 90-degree angle. Tees create a branch line. They are vital for managing water distribution systems in residential and commercial settings.

According to industry reports, the global pipe fittings market reached $60 billion in 2022. Projections suggest growth at a CAGR of 4.5% through 2030. The demand for durable and corrosion-resistant materials has increased. Stainless steel and PVC are popular, but the choice often depends on application needs. This complexity can lead to wrong selections, resulting in costly repairs or replacements.

Fittings also come in various sizes. A mismatch in size can cause leaks or pressure loss. It's essential to consider whether to use threaded, welded, or grooved fittings. Each method has distinct requirements and implications for system integrity. While compatibility is crucial, many overlook installation techniques. Always ensure that the right fittings are used correctly for optimal performance.

When discussing pipe fittings, it's essential to look at the common materials used. Most pipe fittings are made from steel, PVC, copper, and brass.

Steel is popular for industrial uses. It offers strength and durability. PVC is lightweight and ideal for plumbing. Its resistance to corrosion makes it a favorite in many applications.

Copper fittings have been a standard choice for plumbing and HVAC systems. Despite their higher cost, they provide excellent durability. Brass fittings are also widely used. They combine strength with good corrosion resistance.

In fact, reports indicate that the global market for pipe fittings reached around $65 billion in 2021, showing steady growth due to increased infrastructure projects.

Tips: Always consider the working conditions for your pipe fittings. For example, temperature and pressure affect choices. If unsure, consult a professional. Choosing the wrong material can lead to leaks and costly repairs.

Be mindful that not all fittings will perform well in every environment. A material that works well in one setting may fail in another. Always do thorough research before making a decision. The right pipe fitting can save time and money in the long run.

When discussing pipe fittings, it's essential to consider their diverse applications. Different types cater to various systems, whether for residential plumbing or industrial projects. Common categories include elbows, tees, and couplings. Each serves a unique purpose in connecting or redirecting the flow of fluids.

Elbows are often used to make directional changes in piping systems. These fittings can create sharp bends or gradual curves. They come in several angles, such as 90 or 45 degrees. Tees allow for branch connections, creating a “T” shape that enables fluid to flow in different directions. Couplings are straightforward; they connect two pipe ends together.

However, choosing the right type can be tricky. One might overlook the importance of fitting materials. For example, metal and plastic fittings have unique compatibility challenges. Sometimes, users find that a fitting doesn’t match the intended application. These moments can lead to leaks or inefficiencies in the system. It's a reminder that attention to detail matters greatly in piping systems.

When it comes to pipe fittings, installation techniques play a crucial role. The right method ensures durability and prevents leaks. According to the International Association of Plumbing and Mechanical Officials, proper installation can reduce maintenance costs by up to 30%. This statistic highlights the importance of getting it right from the start.

One common technique involves using solvent cement for plastic fittings. The procedure requires cleaning the surfaces before applying cement. It may seem simple, but mistakes can lead to joint failure. Moreover, improper alignment during installation can cause stress on the fitting. This stress may lead to cracks over time. In fact, a study by the American Society of Civil Engineers found that misalignment is a significant factor in pipe system failures.

For metal fittings, welding is a common installation method. When working with this technique, the material must be prepped correctly. This includes clearing paint or rust from edges. However, not all welds are created equal. Inconsistent heat can affect the integrity of the joint. Interestingly, a recent report suggested that up to 15% of welding jobs could fail quality checks. This emphasizes the need for skilled labor in installations.

To ensure the longevity of pipe fittings, regular maintenance is essential. Inspect the fittings periodically for signs of wear or corrosion. Small issues can escalate if overlooked. Look for leaks, cracks, or any other visible damage. Tighten any loose connections as this simple action can prevent more significant problems down the line.

Cleaning is another vital aspect of pipe fittings maintenance. Accumulated dirt can cause blockages. Use a soft brush or cloth to clear any buildup. Make sure to flush the system with clean water regularly. This helps maintain proper flow and function. However, be cautious with cleaning agents; some can be too harsh and damage fittings.

Consider the operating environment too. Extreme temperatures can affect material integrity. Insulate fittings when necessary to prevent thermal shock. When changing parts, ensure compatibility. Using the wrong fittings can lead to leaks or system failure. Yet, even with the best practices, wear and tear happen. It’s a natural part of the lifecycle of pipe fittings. Stay vigilant and be ready to replace components when needed.

| Type of Pipe Fitting | Description | Common Uses | Maintenance Tips |

|---|---|---|---|

| Elbow | Used to change the direction of the pipe. | Pipelines, HVAC systems. | Regularly inspect for signs of wear or corrosion. |

| Tee | Join three sections of pipes, allowing for branching. | Water and sewage systems. | Check joints for leaks and secure fittings |

| Reducer | Connect pipes of different diameters. | Fluid transport systems. | Ensure proper seals and inspect for pressure anomalies. |

| Coupling | Connect two sections of pipe. | General plumbing applications. | Regular checks for secure fitting and possible leaks. |

| Cap | Close the end of a pipe. | End of pipelines and drainage systems. | Inspect for damage and ensure tightness. |

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.