Home // Blog

High-Density Polyethylene (HDPE) pipe has become a popular choice in various industries due to its durability, cost-effectiveness, and numerous environmental benefits. As industry expert Dr. Sarah Thompson, a leading authority in polymer engineering, states, "The use of HDPE pipe not only enhances the efficiency of projects but also significantly reduces the environmental impact compared to traditional materials." This innovative material is favored for its ability to withstand harsh conditions, making it ideal for water supply, drainage systems, and even gas distribution.

In recent years, the demand for HDPE pipe has surged as more sectors recognize its advantages. From reducing installation time to extending service life, HDPE pipe has transformed the way projects are approached. With features like resistance to corrosion and minimal maintenance requirements, it is no wonder that engineers and project managers increasingly advocate for HDPE pipe in their planning and execution processes. This introduction discusses what HDPE pipe is and explores the myriad benefits it offers for various applications, ensuring that your next project can achieve sustainable and efficient results.

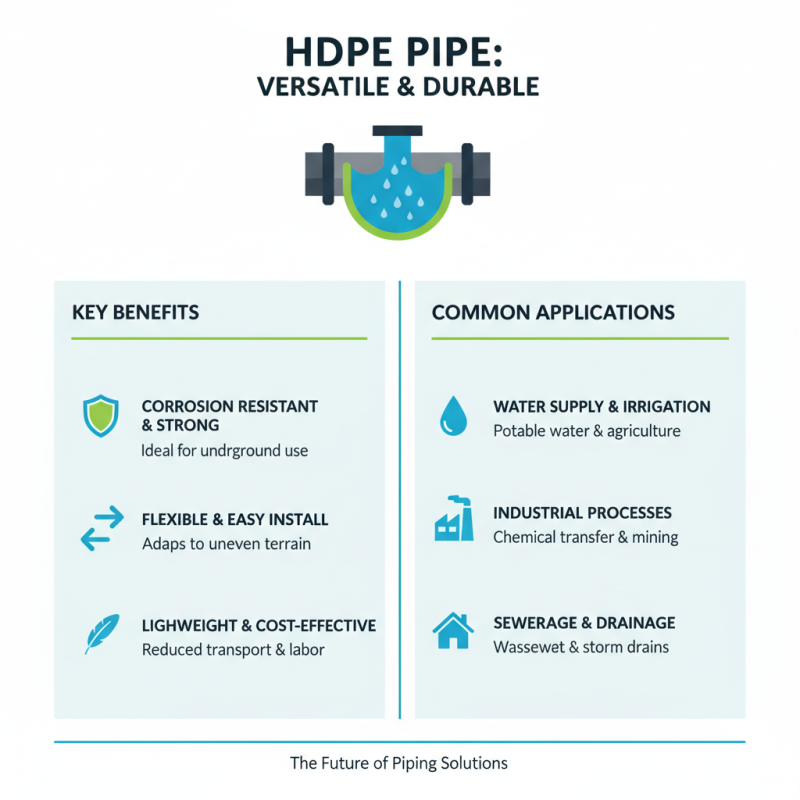

High-Density Polyethylene (HDPE) pipe is a versatile and durable piping solution widely used in various applications, ranging from water supply to industrial processes. Made from high-density polyethylene resin, these pipes are known for their strength and resistance to corrosion, making them ideal for underground installations. The flexibility of HDPE allows for easier installation, even in uneven terrains, and its lightweight nature cuts down transportation costs and labor time.

**Tip: When selecting HDPE pipes for your project, consider the specific requirements of your application, such as pressure ratings and temperature limits. This ensures you achieve optimal performance and longevity.**

Additionally, HDPE pipes are environmentally friendly, as they can be recycled and have a longer lifespan than traditional piping materials. They are also less likely to degrade when exposed to harsh elements, reducing the need for frequent replacements.

**Tip: Look for HDPE pipes that comply with industry standards, such as ASTM or ISO certifications, to ensure you are investing in high-quality materials for your project.** Their resistance to chemical leaching makes HDPE a safe choice for transporting potable water and contributing to more sustainable project outcomes.

HDPE pipe, or high-density polyethylene pipe, is a popular choice in various construction and plumbing projects due to its unique properties. One of its key characteristics is its exceptional durability. HDPE pipes can withstand harsh environmental conditions, making them resistant to corrosion, chemicals, and UV damage. This longevity ensures that projects requiring underground installation can benefit from reduced maintenance costs and an extended service life.

Moreover, HDPE pipes are lightweight and flexible, allowing for easier transportation and installation compared to traditional piping materials. Their flexibility enables them to be used in a variety of applications, including water supply systems, sewage, and storm drainage. Additionally, HDPE’s smooth interior surface minimizes friction and allows for a higher flow rate, increasing the efficiency of the system. This combination of strength, adaptability, and efficiency makes HDPE pipes an ideal choice for modern infrastructure projects.

| Property | Description |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Durability | Resistant to corrosion, impact, and chemicals |

| Flexibility | Can be bent and molded without breaking |

| Weight | Lightweight, making transportation and installation easier |

| Lifespan | Can last 50 years or more under proper conditions |

| Environmental Impact | Recyclable and sustainable material |

| Applications | Widely used in water supply, drainage systems, and industrial applications |

| Installation | Easy to install with various joining methods |

| Cost-Effectiveness | Lower installation and maintenance costs compared to traditional materials |

HDPE (High-Density Polyethylene) pipe is increasingly being recognized for its advantages over traditional piping materials such as PVC or metal. One significant benefit is its enhanced durability, which makes it resistant to corrosion and abrasion. This resilience ensures a longer lifespan, reducing the need for frequent replacements and associated maintenance costs. Furthermore, HDPE pipes are lightweight, making them easier and less expensive to transport and install, which benefits construction efficiency.

Tips for Using HDPE Pipes:

1. **Consider the Environment**: HDPE pipes are often made from recycled materials, providing a sustainable option that aligns with today's eco-friendly initiatives.

2. **Choose the Right Diameter**: Given their flexibility and strength, opt for HDPE pipes with a diameter that matches your project's specific flow requirements to optimize performance.

Moreover, recent advances in materials technology, such as nanoclay reinforcement, are expanding the use of HDPE in various applications, including potential replacements for conventional water pipe materials. As the demand for modern infrastructure continues to grow, particularly in developing regions, the market for HDPE pipes is projected to witness significant expansion, driven by their cost-effectiveness and performance reliability.

HDPE pipes, or high-density polyethylene pipes, are revolutionizing various industries with their unique properties and applications. In 2023, the global fuel pipeline market is projected to reach approximately $221.55 billion, showcasing a robust compound annual growth rate (CAGR) of 5.29% from 2024 to 2031. This growth signals a rising demand for efficient and durable piping solutions, notably in the oil and gas sector.

Common applications of HDPE pipes span across several industries, including water supply, sewage systems, and cooling systems. Recent projects, such as the seawater cooling facility in Saudi Arabia, which saw the successful installation of the world's largest diameter subsea HDPE pipe, further highlight HDPE's essential role in critical infrastructure. The material's excellent corrosion resistance and high strength make it particularly suitable for demanding environments. Reports indicate that the global pellet production market for polymers like HDPE is expanding, with a noticeable increase in applications in construction, automotive, and electronic industries. As we move towards 2025, the emphasis on sustainable and reliable piping solutions continues to drive innovation and growth in the HDPE market.

HDPE (High-Density Polyethylene) pipes are increasingly recognized for their beneficial environmental impact and contribution to sustainability. One of the standout features of HDPE is its recyclability, which significantly reduces waste compared to traditional materials like PVC or metal. Once the pipes reach the end of their lifespan, they can be processed and repurposed into new products, minimizing landfill use and promoting a circular economy.

Additionally, the production of HDPE pipes requires less energy and fewer natural resources than alternatives. Their lightweight nature reduces transportation emissions, and the durability of HDPE ensures a long service life, reducing the environmental footprint associated with frequent replacements. Furthermore, HDPE pipes are resistant to corrosion and chemical damage, which helps in preserving the quality of the water and soil they interact with. This resilience not only extends the life of the infrastructure but also safeguards local ecosystems, making HDPE a smart choice for environmentally conscious projects.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.