Home // Blog

The current price of PVC pipes is a critical concern for builders, contractors, and homeowners alike. With fluctuating costs, understanding the factors influencing the price of PVC pipes is essential for making informed purchasing decisions. According to industry expert John Smith, a senior analyst at Pipe Market Insights, “The price of PVC pipes can vary significantly based on raw material costs, supply chain dynamics, and regional demand fluctuations.” This insight underscores the complexity of PVC pipe pricing, which is tied to various external and internal influences within the market.

In recent years, the PVC pipe sector has experienced notable shifts due to increased demand in various construction projects and the impact of global events that affect manufacturing processes. Such changes can lead to unexpected price surges or decreases. Additionally, factors such as the cost of raw materials, transportation expenses, and regulations play crucial roles in determining the current PVC pipe price. With this understanding, stakeholders can navigate the market more effectively and plan their budgets accordingly, ensuring that they are well-equipped to handle the challenges of pricing in the evolving PVC pipe industry.

The current price trends of PVC pipes in global markets are influenced by a variety of factors that create fluctuations in cost. Recently, there has been an upward trend in prices due to increased demand for construction and infrastructure projects across many countries. As economies begin to recover and grow, the need for reliable piping solutions has surged, raising the demand for PVC products. This heightened demand places pressure on production facilities, leading to higher operational costs, which are subsequently reflected in the price of PVC pipes.

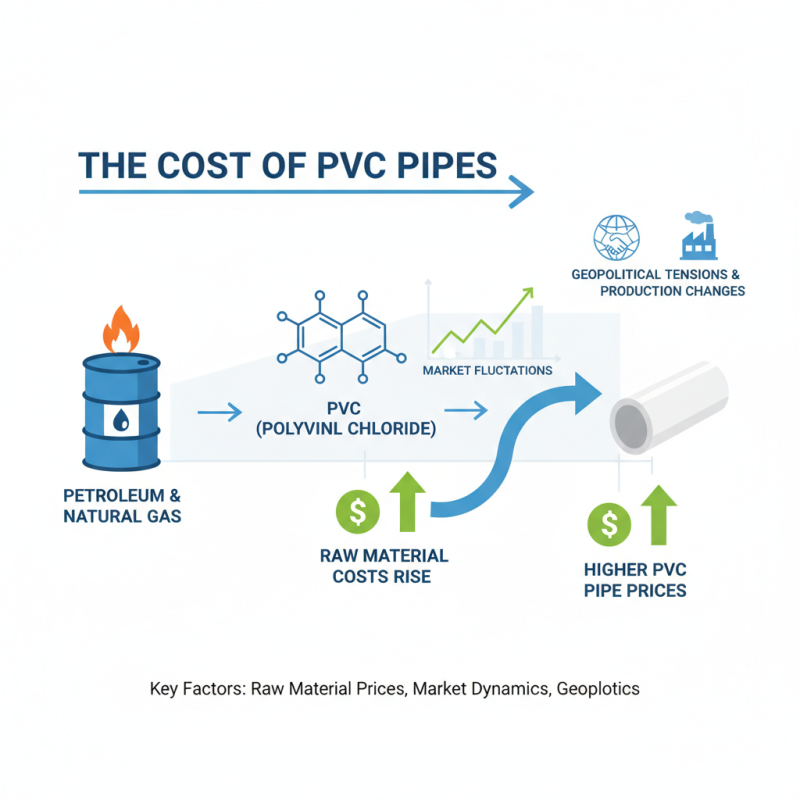

In addition to demand, the cost of raw materials significantly impacts the pricing of PVC pipes. The prices of crude oil, natural gas, and other petrochemical inputs have experienced volatility, which directly affects the manufacturing costs of PVC. Supply chain disruptions, caused by geopolitical issues or natural disasters, have also played a role, causing delays and increasing transportation costs. Moreover, regulatory changes regarding environmental standards may compel manufacturers to invest in cleaner technologies, further impacting the overall cost structure. Thus, the combination of high demand, raw material prices, and potential supply chain challenges are key factors shaping the current trends in PVC pipe pricing worldwide.

The cost of PVC pipes is influenced by a variety of factors that reflect both market dynamics and manufacturing variables. One of the most significant contributors to the price fluctuation is the cost of raw materials, particularly vinyl chloride monomer (VCM) and ethylene, which are essential to PVC production. According to a market analysis by Grand View Research, the price of these raw materials can vary due to supply chain disruptions, changes in crude oil prices, and fluctuations in demand across different sectors, especially the construction and plumbing industries. For instance, a spike in oil prices can lead to increased costs in production, subsequently affecting the final price of PVC pipes.

Another key factor influencing PVC pipe costs is the production capacity and technology employed by manufacturers. As reported by Research and Markets, advancements in manufacturing processes can lower operational costs, allowing producers to offer competitive pricing. Moreover, regional differences in production capabilities and logistics can also create price disparities. For example, regions with established infrastructure for transporting raw materials often experience lower costs, while areas reliant on imports may face higher prices. Additionally, environmental regulations and sustainability initiatives are gaining traction, which may impose additional costs that manufacturers might pass on to consumers, further impacting the overall pricing of PVC pipes.

This chart illustrates the key factors influencing the cost of PVC pipes as a percentage. The raw material costs have the most significant impact, followed by production and transportation costs. Market demand and environmental regulations also play a crucial role in determining prices.

The cost of PVC pipes is significantly influenced by the prices of raw materials used in their production. PVC, or polyvinyl chloride, is primarily derived from petroleum and natural gas. Fluctuations in the prices of these fossil fuels due to market dynamics, geopolitical tensions, or changes in production rates can directly impact the production costs of PVC. As raw material costs rise, manufacturers often pass these increases onto consumers, resulting in higher retail prices for PVC pipes.

Additionally, the availability of additives and stabilizers that enhance the properties of PVC also contributes to cost variability. For example, fluctuations in the prices of calcium carbonate, titanium dioxide, and other fillers can lead to varying production expenses. Supply chain disruptions, whether from environmental factors or logistical challenges, further exacerbate these price changes. Therefore, professionals in the construction and plumbing industries must stay informed about raw material trends as they significantly affect the overall pricing structure of PVC pipes in the market.

The pricing of PVC pipes is significantly influenced by supply chain dynamics, which encompass various factors including manufacturing, transportation, and market demand. As raw materials like PVC resin are procured, any volatility in their availability or price directly affects the cost of the finished product. Transportation costs, often subject to fluctuations due to fuel prices and logistical challenges, further complicate the pricing structure. Delays in shipping or production can lead to scarcity in the market, driving prices upward as demand remains constant or increases.

Additionally, market trends play a critical role in shaping supply chain dynamics. An increase in demand for construction and infrastructure projects typically leads to higher consumption of PVC pipes. This surge places additional pressure on manufacturers who may face challenges in ramping up production to meet the immediate needs, thus impacting pricing. Seasonal factors can also contribute, as demand can spike during certain times of the year based on construction schedules or renovation cycles. As a result, the interplay of these elements can lead to significant fluctuations in PVC pipe prices, making it essential for stakeholders to stay informed about current market conditions and supply chain status.

| PVC Pipe Diameter (inches) | Current Price (USD per foot) | Price Change (Last Month %) | Supply Chain Factor |

|---|---|---|---|

| 1.5 | $0.90 | +5% | Increased demand |

| 2.0 | $1.25 | +3% | Material shortages |

| 3.0 | $1.80 | +10% | Logistics delays |

| 4.0 | $2.50 | -2% | Stable supply |

| 6.0 | $3.75 | +8% | Increased freight costs |

PVC pipe prices can vary significantly across different regions due to a multitude of factors. According to a recent industry report by the Plastics Pipe Institute, the average price of PVC pipes can differ as much as 20% to 30% from one region to another. This disparity is often influenced by local demand, transportation costs, and regional production capabilities. For instance, areas with robust construction activities, such as Texas and California, tend to see higher prices, driven by increased competition for raw materials and tighter supply chains.

Additionally, variations in raw material costs, such as the price of ethylene and chlorine, directly affect PVC pipe pricing. These materials are largely impacted by global oil prices and regional supply constraints. Furthermore, the presence of manufacturing plants in certain areas can lead to lower costs due to reduced shipping expenses. As reported by the American Council for an Energy-Efficient Economy, states with abundant natural gas resources may also experience lower PVC pipe costs, as natural gas is a crucial feedstock in PVC production.

Tip: Always consider local market conditions and factor in shipping costs when purchasing PVC pipes, as these can greatly influence overall expenses.

Tip: Keep an eye on regional economic trends, as fluctuations in construction activity can lead to sudden price increases or decreases in PVC pipes.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.