Home // Blog

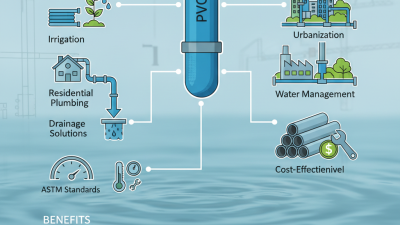

When undertaking plumbing projects, the selection of the appropriate PVC pipe fittings is crucial to ensure the integrity and efficiency of the system. PVC pipe fittings serve as vital components that connect various sections of piping, allowing for the proper flow and direction of water within residential and commercial plumbing systems. With a multitude of options available on the market, choosing the right fittings can seem overwhelming for both novice and experienced DIYers.

Understanding the different types of PVC pipe fittings, their specific applications, and the standards to consider is essential for achieving a successful plumbing installation. Factors such as the size, pressure rating, and compatibility with existing plumbing materials must be taken into account. Moreover, educating oneself about the installation methods and potential limitations of different fittings can further enhance the overall performance of the plumbing system. By making informed choices, homeowners and professionals alike can ensure a reliable and durable plumbing infrastructure that meets their project needs.

When embarking on a plumbing project, understanding the various types of PVC pipe fittings is crucial for ensuring a functional and reliable system. PVC fittings come in several forms, each designed to accommodate specific plumbing needs. For example, elbow fittings are used to change the direction of the pipe, allowing for corners and turns in the piping layout.

Tees, on the other hand, create a junction where three pipes meet, which is essential for branching off a line in different directions.

Tees, on the other hand, create a junction where three pipes meet, which is essential for branching off a line in different directions.

In addition to elbows and tees, there are also couplings, which connect two pieces of pipe, and adapters that transition from PVC to different materials. Another important type is the plug, used to seal the end of a pipe or fitting, making it vital for closing off unused lines. The choice of fitting greatly impacts flow efficiency and installation ease, so it’s important to consider the specific requirements of your project, such as pressure ratings and fittings’ compatibility with the pipe diameter. By selecting the right PVC pipe fittings, you can enhance the longevity and effectiveness of your plumbing system.

When embarking on plumbing projects, selecting the right size and diameter of PVC pipe fittings is crucial. The size of the fitting must match the pipe's diameter to ensure a proper seal and effective flow of water. Standard pipe diameters typically range from ½ inch to 6 inches for most residential applications. Measure the outer diameter of the pipe if you're unsure, as fittings are usually available in both nominal and actual measurements.

Tips: Always refer to plumbing codes and specifications for your area to ensure compliance, as this can prevent costly setbacks in your project. Additionally, consider the intended use of the plumbing system; for instance, larger diameters are necessary for high-demand applications such as main water supply lines, while smaller diameters might suffice for irrigation or drainage.

It's also important to consider the pressure ratings and material compatibility when selecting fittings. PVC fittings come in different classes, so matching the fitting class to the intended pressure rating of your system is vital. As a further tip, purchasing fittings from the same manufacturer can help ensure consistency and compatibility, reducing the chances of leaks and failures in your plumbing projects.

When evaluating the quality and standards of PVC pipe fittings for plumbing projects, it is essential to consider the materials used in their manufacture. High-quality PVC should be durable, resistant to corrosion, and able to withstand the pressures associated with household plumbing systems. Look for fittings that meet or exceed industry standards such as ASTM or NSF certifications. These certifications ensure that the products have been tested for safety, performance, and longevity, which is crucial for avoiding potential leaks and costly repairs in the future.

Another important factor in assessing PVC pipe fittings is the consistency of manufacturing processes. Quality control measures should be in place to ensure that each fitting meets the required specifications consistently. This includes checking for uniform thickness, proper dimensions, and smooth surfaces, which can reduce the risk of joint failures. Additionally, understanding the specific application requirements—such as temperature and pressure ratings—can guide you in selecting fittings that are optimized for your particular plumbing needs. By prioritizing quality and adhering to established standards, you can significantly enhance the reliability and performance of your plumbing installations.

When selecting PVC pipe fittings for plumbing projects, it is essential to consider the environmental impact of the materials used. PVC, or polyvinyl chloride, is a widely used plastic that enjoys popularity due to its durability and versatility. However, the production and disposal of PVC can lead to environmental concerns, including the release of harmful chemicals. Therefore, opting for PVC fittings that adhere to stringent environmental standards can help mitigate these issues. Look for products that are certified as environmentally friendly, as they often undergo rigorous assessments to ensure minimal impact on ecosystems.

Longevity is another critical factor to consider when choosing PVC materials. High-quality PVC pipe fittings can offer an extensive lifespan, often exceeding 50 years with proper care and installation. This longevity not only enhances the efficiency of plumbing systems but also reduces the need for frequent replacements, consequently lowering waste. When selecting fittings, examine the specifications and durability ratings to ensure that they meet longevity requirements suitable for your specific plumbing application. By prioritizing both environmental considerations and material durability, you can make informed decisions that contribute to sustainable and efficient plumbing solutions.

Installing PVC pipe fittings requires precision and the right tools to ensure a leak-free connection in your plumbing projects. Start with essential tools such as a pipe cutter or hacksaw for cleanly cutting the PVC pipes. A deburring tool can help smooth out the edges of the cut pipes, reducing the chance of damage to the fittings and ensuring a secure fit. Additionally, having a measuring tape, rubber gloves, and a primer and solvent cement specifically designed for PVC will streamline the installation process.

When you're ready to install, begin by measuring and cutting your pipes to the desired lengths. Before joining the fittings, apply primer to both the pipe and the fitting to prepare the surfaces for bonding. After the primer dries, apply the solvent cement evenly on both surfaces, then quickly insert the pipe into the fitting with a twisting motion to ensure a good seal. Hold the connection for about 30 seconds to allow the bond to set. Always work in a well-ventilated area and follow the manufacturer’s instructions for the best results. Taking these steps not only guarantees a strong connection but also helps prevent future plumbing issues.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.