Home // Blog

PVC (Polyvinyl Chloride) pipes have become an integral component of numerous industries, due to their remarkable durability, cost-effectiveness, and versatility. According to the Plastics Industry Association, the demand for PVC pipes is on the rise, driven by their extensive applications in construction, agriculture, and municipal water systems. In fact, a recent industry report highlighted that the global PVC pipe market is projected to reach USD 62 billion by 2027, reflecting an annual growth rate of over 6%.

The "8 PVC Pipe" uses we are about to explore underscore how this material has revolutionized plumbing, drainage systems, and even electrical conduits. From providing solutions for complex plumbing layouts to ensuring efficient water management in irrigation systems, PVC pipes offer unparalleled advantages. Additionally, their lightweight nature and easy installation further enhance their usability across various projects.

Understanding the benefits of the "8 PVC Pipe" applications not only illustrates their importance in day-to-day operations but also exemplifies their role in sustainable practices. With a growing emphasis on green construction practices and infrastructure resiliency, PVC pipes emerge as a reliable choice that aligns with the industry's evolving demands.

When it comes to construction and plumbing applications, PVC (polyvinyl chloride) pipes are a popular choice due to their versatility, durability, and resistance to corrosion. PVC pipes are commonly used for water supply lines, drainage systems, and vent piping. They are lightweight, making them easy to handle and install, which significantly speeds up the construction process. Additionally, their smooth interior surface allows for efficient water flow while reducing the chances of clogs.

For any construction or plumbing project utilizing PVC pipes, it's essential to keep a few tips in mind. First, ensure proper sizing of the pipes according to the specific requirements of your project. Using the correct diameter is crucial for optimal fluid flow and pressure management. Second, when cutting and fitting, always use the appropriate tools to achieve a clean cut, which will ensure better connections and reduce the risk of leaks. Lastly, when joining PVC pipes, never skip on proper solvent cement application, as this will solidify the bond and enhance the overall durability of the piping system.

Overall, the integration of PVC pipes in construction and plumbing not only improves efficiency but also ensures a long-lasting solution for any water-related applications. Their benefits, from cost-effectiveness to ease of maintenance, make them an indispensable part of modern building practices.

PVC pipes are increasingly recognized for their exceptional durability and cost efficiency, making them a preferred choice across various industries. According to the Plastics Industry Association, PVC pipes are designed to last for over 50 years, significantly outperforming traditional materials like metal and concrete. This longevity not only translates into reduced replacement costs but also minimizes the need for frequent maintenance, providing substantial savings over the lifecycle of the piping system.

In addition to their durability, PVC pipes offer a remarkable cost efficiency that sets them apart in the construction and plumbing sectors. A report from the American Water Works Association reveals that the installation cost of PVC pipes can be up to 35% lower than that of comparable materials. This cost advantage is further enhanced by their lightweight nature, which simplifies transportation and installation processes. Furthermore, PVC pipes do not corrode or rust, reducing the risk of leaks and the associated repair costs, while also ensuring efficient fluid flow without contamination. These attributes make PVC pipes not only a practical choice but also an economically sound investment for both residential and commercial applications.

PVC pipes are widely recognized for their versatility in various applications, but their environmental impact is a pertinent concern. One of the critical aspects to consider is the recyclability of PVC. Unlike some other plastic materials, PVC can be recycled multiple times without significant degradation of its properties. This feature makes it an attractive option for reducing the demand for virgin materials, thereby conserving resources and minimizing waste. In many regions, PVC recycling programs are in place, facilitating the collection and repurposing of discarded pipes into new products, further promoting a circular economy.

Sustainability is another core benefit linked to PVC pipe usage. The production of PVC pipes typically consumes less energy compared to alternative materials, such as metal or concrete, which enhances their environmental footprint during manufacturing. Additionally, PVC's durability contributes significantly to its lifecycle impact; pipes made from this material often have a long service life, reducing the need for frequent replacements. This longevity decreases the overall environmental impact, as less energy and resources are required for production and installation over time. Thus, considering their recyclability and the sustainable practices surrounding their production and usage, PVC pipes present a compelling case in the ongoing conversation about eco-friendly building materials.

When comparing PVC pipes to other materials such as copper, steel, and polyethylene, several factors come into play, influencing their suitability for various applications. PVC, or polyvinyl chloride, is known for its lightweight nature and resistance to corrosion, making it an ideal choice for plumbing and drainage systems.

In contrast, while copper pipes offer excellent durability and are naturally antimicrobial, they can be significantly more expensive and prone to issues such as galvanic corrosion. Steel pipes, on the other hand, are robust and can handle high-pressure applications, but they are susceptible to rust and require protective coatings, adding to maintenance costs.

Another critical aspect to consider in this comparative analysis is the ease of installation and flexibility of PVC. Unlike rigid materials like steel, PVC can be easily cut and joined, facilitating quick installation and repairs. Its flexibility also allows for better handling through tight spaces and around obstacles. Additionally, PVC pipes do not require special tools for installation, which can save both time and labor costs. Thus, while other materials have their merits, the combination of cost-effectiveness, ease of use, and resistance to environmental stressors positions PVC as a highly advantageous option in many applications within the industry.

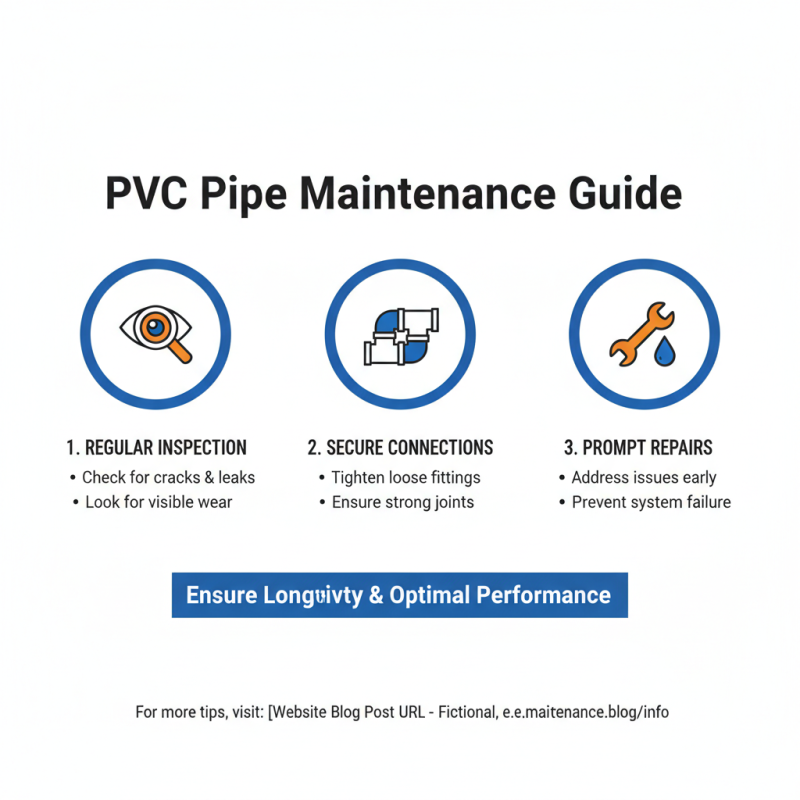

Maintaining PVC pipes is essential to ensure their longevity and optimal performance. Regular inspection is the first step in the maintenance process. Check for any visible signs of wear, such as cracks or leaks, and address these issues promptly. It's also important to ensure that joints and connections are secure; loose fittings can lead to leaks that compromise the integrity of the entire system.

**Tips for Maintenance:**

- **Regular Cleanings:** Periodically clean your PVC pipes using a mixture of warm water and mild soap. This helps prevent the build-up of debris and reduces the chances of clogs developing over time.

- **Avoiding Harsh Chemicals:** While it might be tempting to use strong chemicals for cleaning, it’s crucial to avoid products that can damage PVC. Opt for gentle, non-corrosive cleaners to maintain the integrity of the pipes.

In addition to inspections and cleanings, it's vital to consider the environmental factors that may affect your PVC pipes. For instance, extreme temperatures can cause pipes to expand or contract. Insulating your pipes can help mitigate the effects of temperature fluctuations, preserving their functionality. Staying proactive with these maintenance practices will help extend the life of your PVC piping system while ensuring it operates efficiently.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.