Home // Blog

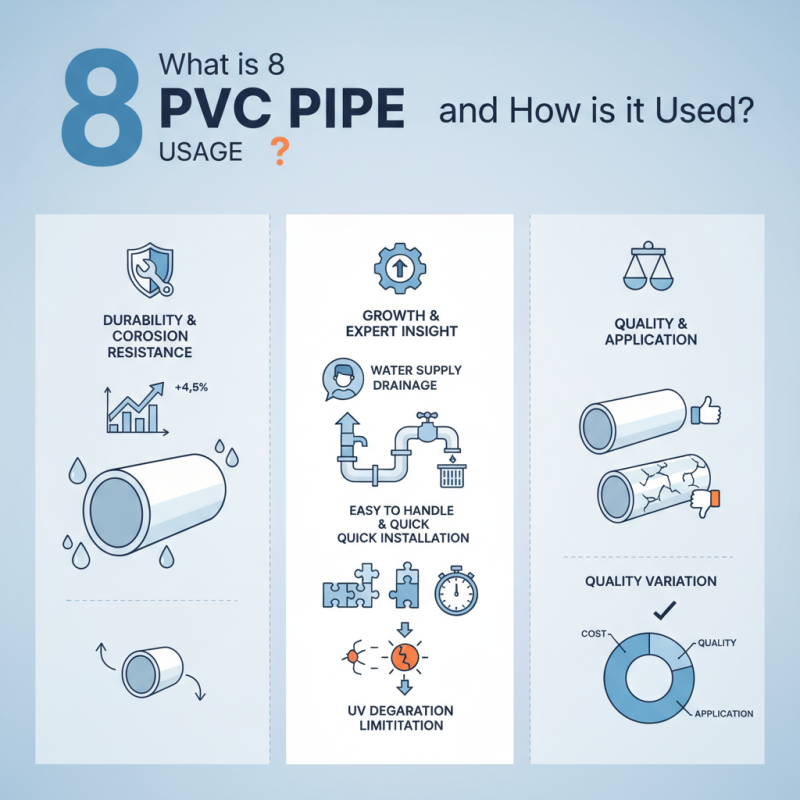

The 8 PVC pipe is a crucial component in various plumbing and construction applications. According to the American Society for Testing and Materials (ASTM), this type of pipe offers excellent durability and resistance against corrosion. Industry experts estimate that the demand for PVC pipes will grow by 4.5% annually throughout the next decade. This growth highlights the importance of understanding the use and benefits of 8 PVC pipe.

Dr. John Michaels, a well-known authority in plumbing materials, emphasizes, "The reliability of 8 PVC pipes makes them a preferred choice among contractors." These pipes are used not only for drainage systems, but also for water supply lines. They are lightweight, easy to handle, and can be installed quickly. However, it’s essential to consider their limitations, such as susceptibility to UV degradation over time.

While the advantages of 8 PVC pipe are clear, it’s not without its challenges. Quality can vary significantly across manufacturers. Higher standards in production lead to better performance, while cheaper alternatives might fail under pressure. Evaluating the true value of 8 PVC pipe involves balancing cost, quality, and intended application. Choosing the right type matters greatly in every project.

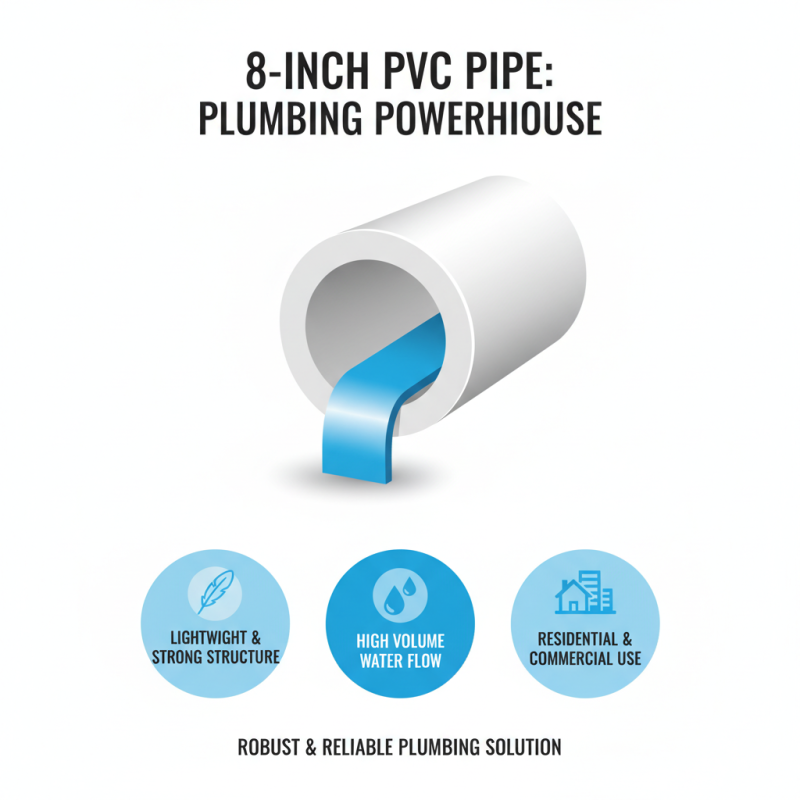

The 8-inch PVC pipe is a popular choice in various construction and plumbing applications. It is known for its durability and versatility. Commonly used in drainage, irrigation, and sewage systems, it manages a significant flow of water. With a diameter of 8 inches, it can accommodate large volumes. This makes it ideal for municipal projects, industrial uses, and residential settings.

Specifications of an 8-inch PVC pipe include its pressure rating, thickness, and length. The pipe comes in various lengths, often 10 or 20 feet. The thickness varies based on its intended use. For example, some may require thicker walls for high-pressure systems. The material is lightweight, which makes for easier handling and installation.

While the benefits are clear, some might find challenges in connecting these pipes. Misalignment can lead to leaks or blockages. It's crucial to check fittings properly. Additionally, understanding local codes and regulations is important but often overlooked. Each project has unique demands that should be reviewed carefully, ensuring that all specifications are met.

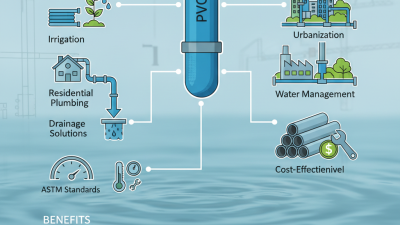

8-inch PVC pipe is versatile and widely used across different industries. Its durability and resistance to corrosion make it suitable for various applications. In construction, it often serves as a drain for stormwater systems. Many builders appreciate its strength in handling significant water flow. It can withstand the rigors of everyday use, which is a plus.

In agriculture, this pipe is a common choice for irrigation systems. Farmers rely on it to transport water efficiently. The ability to create long runs without significant pressure loss is essential. However, improper installation may lead to leaks. Such issues can significantly hinder productivity.

Another critical area for 8-inch PVC pipes is in industrial settings. Factories use them for chemical transport and wastewater management. This application requires careful consideration of material compatibility. While PVC pipes are effective, there’s a risk of degradation in harsh chemical environments. Regular inspection can mitigate potential problems. In these cases, good practices are crucial for maintaining efficiency and safety.

8-inch PVC pipe is a popular choice for plumbing applications due to its robust characteristics. It is lightweight yet provides strong structural integrity. This pipe size is ideal for handling high volumes of water, making it suitable for both residential and commercial projects.

One significant advantage of using 8-inch PVC pipe is its corrosion resistance. Unlike metal pipes, PVC won’t rust or corrode over time. This means lower maintenance costs and longer service life. The smooth interior also helps in maintaining flow efficiency. Over time, users notice fewer clogs and reduced pressure loss.

Tips: When installing PVC, ensure all joints are sealed properly. A well-sealed pipe can prevent leaks. Additionally, proper support spacing is vital. If the supports are too far apart, the pipe might sag, causing future issues. Always double-check your measurements before cutting.

However, it’s important to consider your local regulations. Not all areas permit PVC pipes for certain applications. You may find restrictions based on building codes or environmental concerns. Be mindful of these while planning your plumbing system. A simple research might save you time and money in the long run.

When discussing 8-inch PVC pipe, industry standards and regulations play a critical role. These standards ensure the pipe meets safety requirements. They cover aspects like pressure ratings, installation methods, and material specifications. In many regions, adherence to these regulations is mandatory for plumbing and construction projects.

Tips for proper use: Always consult local codes before installation. Some areas have specific requirements for PVC piping. Ensure you are familiar with them to avoid future complications. Misunderstanding the regulations could lead to costly repairs or replacements.

Quality control is essential when selecting PVC pipe. It should be tested for durability and pressure capacity. Look for compliance markings on the pipe. However, it’s crucial to evaluate whether these markings genuinely reflect the pipe's quality. Don't rely solely on manufacturer claims. Seek third-party verification when possible.

The handling of 8-inch PVC pipe requires care. Improper installation can lead to leaks or failures. Make sure to check for visible defects before use. Inconsistent wall thickness or cracks are red flags. Take your time to ensure everything is up to standard. Rushing can compromise the integrity of your project.

This chart illustrates the usage frequency of 8 inch PVC pipes across various industries. As indicated, the utility sector holds the largest share, followed by the construction industry.

When comparing 8-inch PVC pipe to other materials, several aspects come into play. PVC pipes are favored for their lightweight nature. They are easy to handle and require less labor for installation. Data shows that PVC has a lower installation cost than metal pipes, often around 25% less. This can significantly reduce project budgets.

On the other hand, metal pipes, such as cast iron, are often more durable but at a higher cost. Their installation is heavier and more complex. A report notes that while metal pipes last longer, they can corrode over time. PVC, however, is resistant to many chemicals and does not rust, making it suitable for various applications, including drainage and plumbing.

Not everything about PVC is perfect. Some studies highlight the environmental impact of PVC production. Additionally, it can become brittle in extreme temperatures. The longevity of PVC pipes is generally good, yet fluctuations in temperature range can lead to potential issues. Considering these factors is essential for making the right choice in piping systems.

© Copyright 2025 PolyFab Plastic Industry LLC. All Rights Reserved.